1. Title: Enhanced Mechanical Properties of Carbon Nanotube/ Aluminium Composites Fabricated by Powder Metallurgical and Repeated Hot-Rolling Techniques

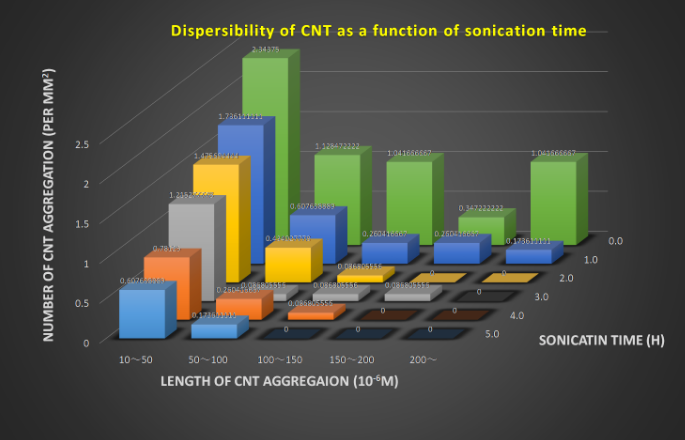

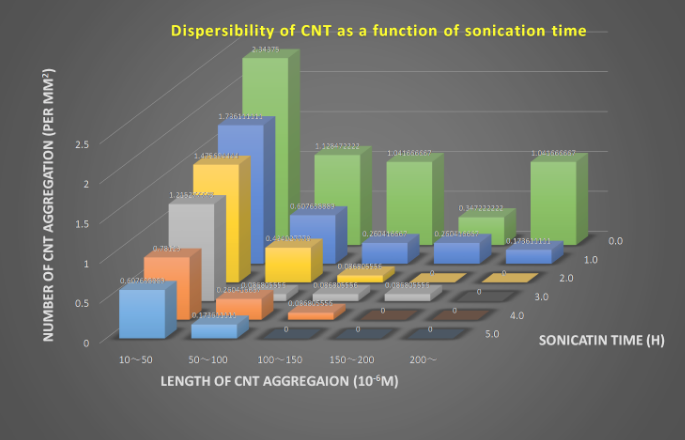

Content: This research aims to fabricate lightweight and high-strength carbon nanotube (CNT)/ aluminium (Al) composites by powder metallurgical and repeated hot-rolling techniques. The fabrication has been conducted in three steps: (1) CNT dispersion, (2) preparation of CNT/ Al compacts by powder metallurgical slurry methods, and (3) strengthening and refining of CNT/ Al composites by repeated hot rolling. Enhanced mechanical properties of the composites has been examined in relation to the microstructures.

(a) (b)

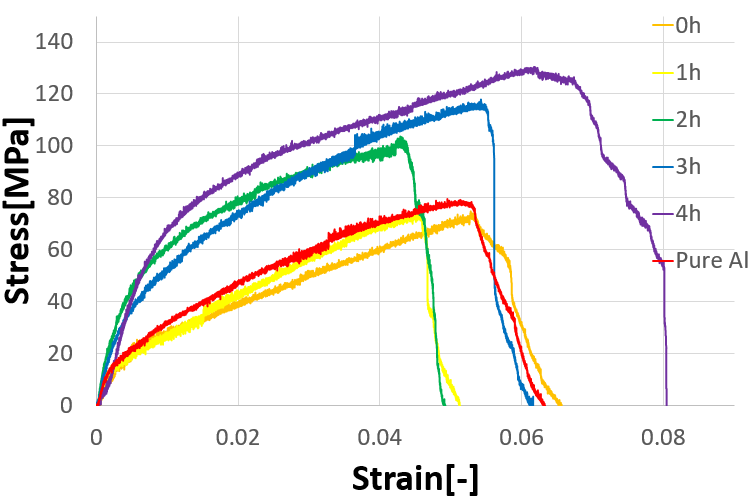

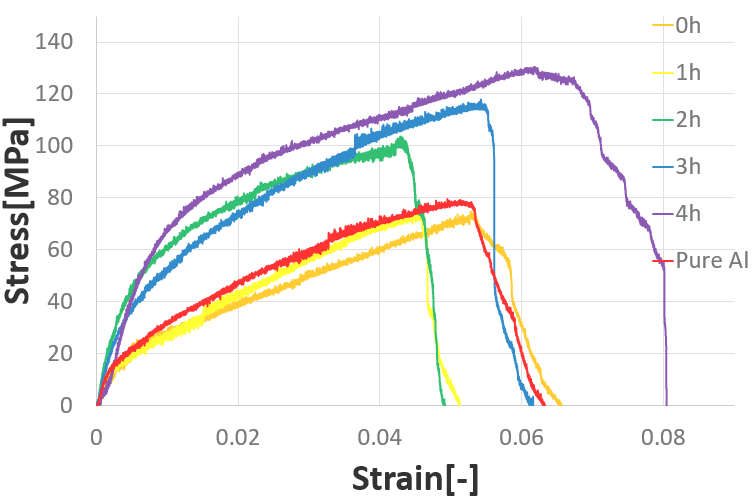

Dispersibility of CNT (a) and stress-strain curves (b) for CNT (0.5 mass %)/ Al composites

as a function of sonication time.

2. Title: Fabrication of Carbon Nanotube/ Aluminum Matrix Functionally Graded Materials using Centrifugal Slurry Methods

Content: Carbon nanotube (CNT) has received broad scientific andindustrial attention due to their excellent mechanical and functional properties. However, CNT has not been effectively used for high performance composites because of degradation of mechanical properties due to insufficient dispersibility of CNT. In this study,CNT/ aluminium (Al) matrix functionally graded materials (FGMs) have been focused on. The processes of dispersion of CNT have been carried out with the solvent of dimethylacetamide, and the dispersing agent of potassium carbonate, which is an inorganic salt, under ultrasonic sonication conditions. Centrifugal slurry methods have been applied to obtain gradient of content of CNT in CNT/ Al matrix FGMs. Tribological characteristics on CNT/ Al matrix FGMs have been investigated using a ball-on-disk tribometer.

(a) (b)

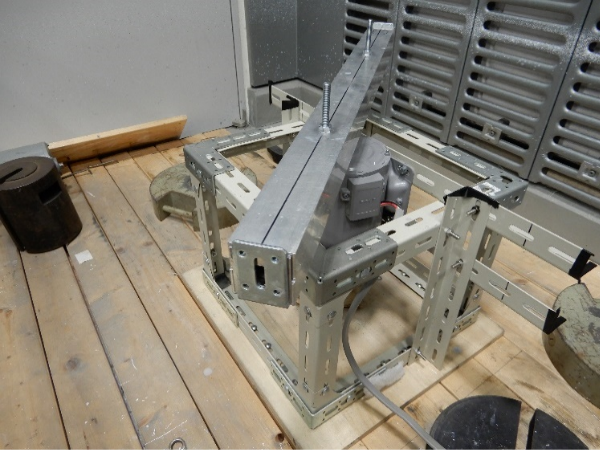

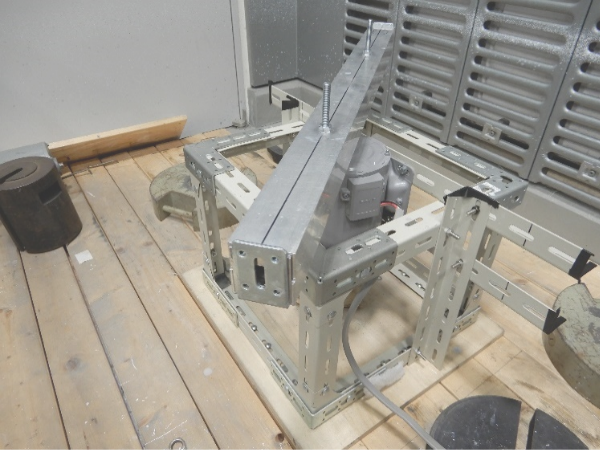

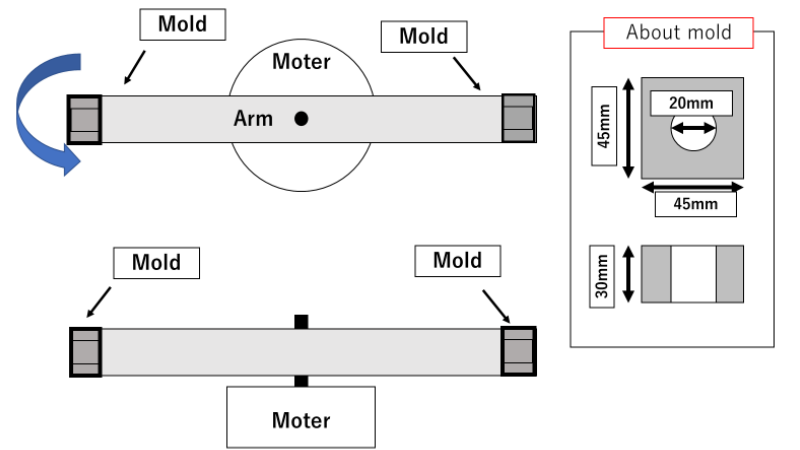

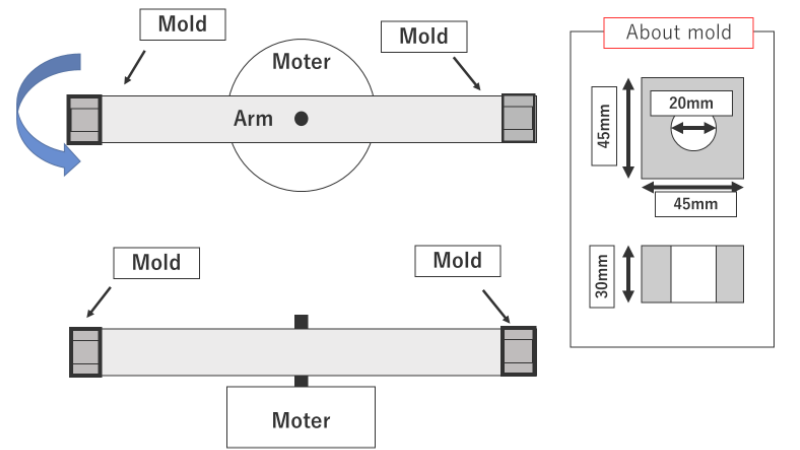

Set-up of a centrifugal slurry equipment, (a) apparatus photo and (b) schematic illustration.

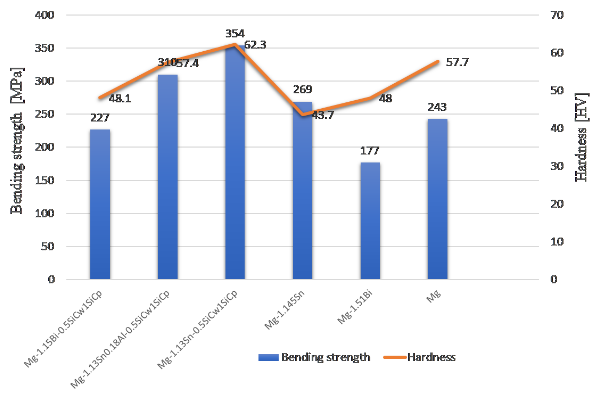

3. Title: Enhanced Mechanical Properties of SiCw/ SiCp-reinforced Magnesium Composites Fabricated by Spark Plasma Sintering

Content: This study aims to fabricate SiC whisker (w)/ particle (p)-reinforced magnesium (Mg) composites with enhanced mechanical properties using spark plasma sintering (SPS) methods. It was demonstrated that dispersing state of SiCw can be improved by addition of SiCp. However, due to presence of some voids and cracks between the oxide layers and Mg matrix, Mg-0.5vol.%SiCw1vol.%SiCp composites showed lower bending strength than Mg-0.5vol.%SiCw, Mg-3vol.%SiCp composites and pure Mg. This issue can be tackled by adding some low melting point metals into the composites to fillingthe voids and cracks.

Bending strength and micro Vickers hardness for the composites with

low meting point metals of Sn, Sn-Al and Bi

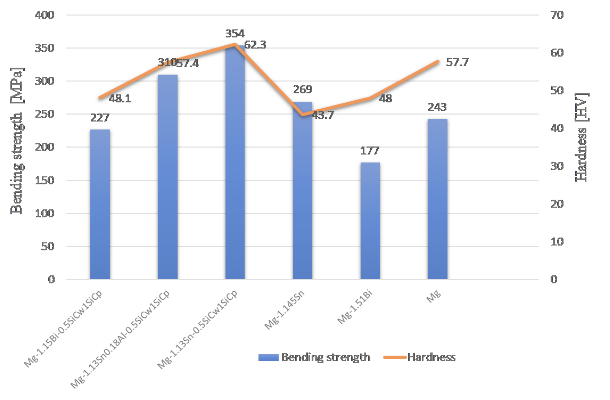

4. Title: Enhanced Mechanical Properties of Carbon Nanotube-Reinforced Magnesium Composites Fabricated by Spark Plasma Sintering

Content: This study aims to enhance carbon nanotube (CNT)-reinforced magnesium (Mg) matrix composites fabricated by spark plasma sintering (SPS). Ultrasonic treatment with organic solvent(DMAc) and dispersant(K2CO3)has been used for the processes to make each CNT apart. Nano-order ceramic powders of zirconia (ZrO2) have been found to be effective to keep uniform dispersion of CNT in Mg matrix. Low melting point metals such as Sn and Bi were added to fillvoids and cracks in the composites. Post-SPS rolling was also employed aiming to improve the microstructures. The fabricated CNT-reinforced Mg composites have been investigated on mechanical properties such as hardness and three-point bending strength to be related to the microstructures.

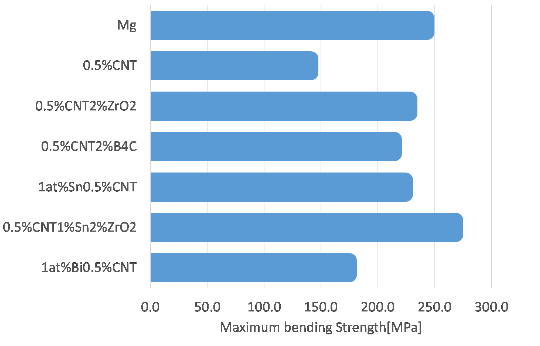

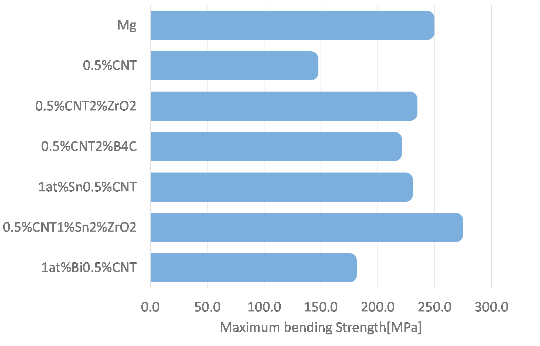

Maximum bending strength for Mg and Mg matrix composites

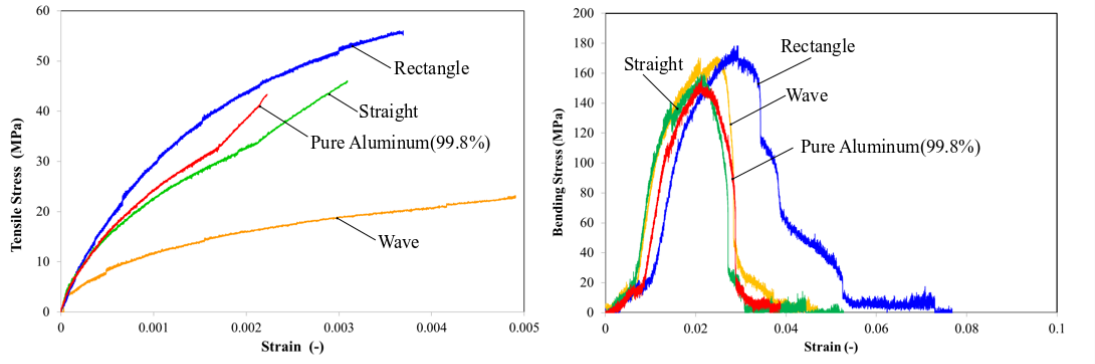

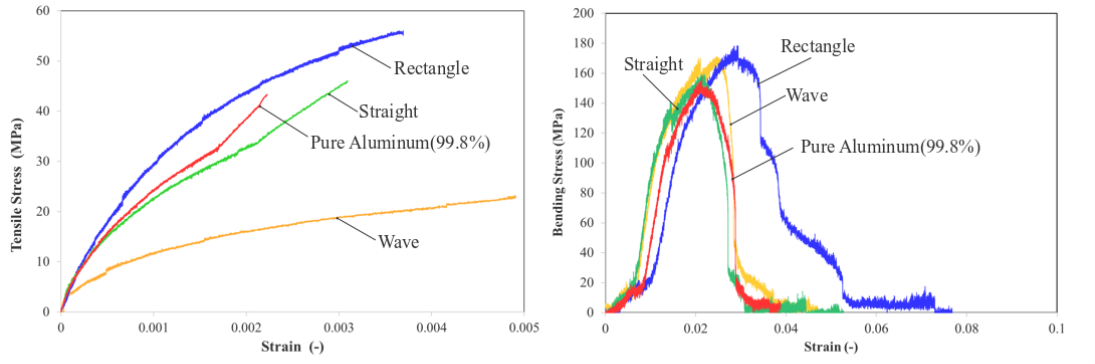

5. Title: A Study on Anisotropic Mechanical Behaviour of Shape Memory Alloy Reinforced Aluminium Matrix Composites

Content: This study aims to investigate mechanical behavior of Ti-Ni shape memory alloy (SMA) long-fiber reinforced aluminum (Al) matrix composites fabricated by powder metallurgical techniques. SMA fibers with three different pre-memorized shapes were prepared; straight fiber, wave-shape fiber and rectangle-shape fiber. Three-point bending and tensile test results demonstrated that wave-shape SMA/ Al composites showed the highest elastic modulus, and wave-shape and rectangle-shape SMA/ Al composites showed high Poisson’s ratio (longitudinal-lateral strain ratio in elastic and plastic deformation regimes). It can be concluded that internal stresses in the composites, which were introduced during the fabrication processes, highly affect their elastic and plastic anisotropy and strength.

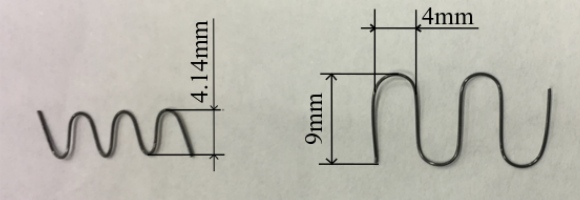

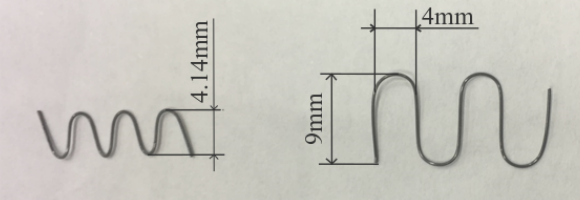

Configurations of SMA fibers (wave and rectangle)

(a) (b)

Tensile stress-strain curves (a) and maximum bending stress-strain curves (b)